What Are They Doing in There?

While walking around an old office building you turn a corner and spot something reminiscent of the final scenes in “E.T. The Extraterrestrial.” Ceiling to floor plastic sheets. Whirring machines and red tape. “Danger: Asbestos” and “Decontamination Unit” signage. You instinctively freeze and question-what are they doing in there?

Worry not! These are all signs of a controlled and carefully planned asbestos abatement setup. While this equipment and signage may initially give you an uneasy feeling, these measures are in place for the safety of both technicians and the public.

Asbestos abatement consists of specific engineering controls which include proper site setup and postings, lock out/tag out of utilities and energy sources, critical barriers, wet methods, HEPA vacs, decontamination, negative air, and additional safety and prompt cleanup measures.

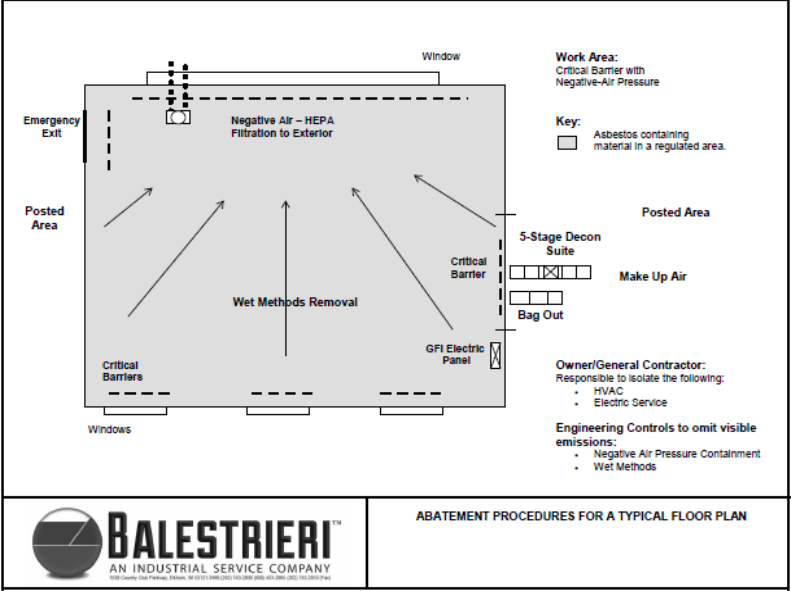

A typical floor plan for a negative air pressure containment involves first creating a footprint of the critical barrier. This area is then sealed off with polyethylene sheeting and sealed to ensure no airborne materials can get out of the containment area. Any central air ducts within the containment are also sealed off as part of preparation. ACM (Asbestos Containing Materials) are wetted down to reduce the likelihood of fibers becoming airborne. A negative air – HEPA filtration unit, decontamination unit, and load-out area will be installed around the perimeter of the footprint.

A negative air – HEPA filtration unit filters any and all air leaving the containment area to 99.97% efficiency. The decontamination unit is the only area technicians are able to enter or exit in the containment area. Decon units typically consist of a clean room, a shower room, and an equipment room, separated from each other and the regulated air, by airlocks. The load-out area is where all ACM will be properly containerized, labeled, and eventually transported to an accredited landfill with a written manifest for disposal records. Required PPE for workers include a hard hat, safety glasses, steel-toe boots, high visibility vests, gloves, respirators, a head-to-toe Tyvek suit, and coveralls.

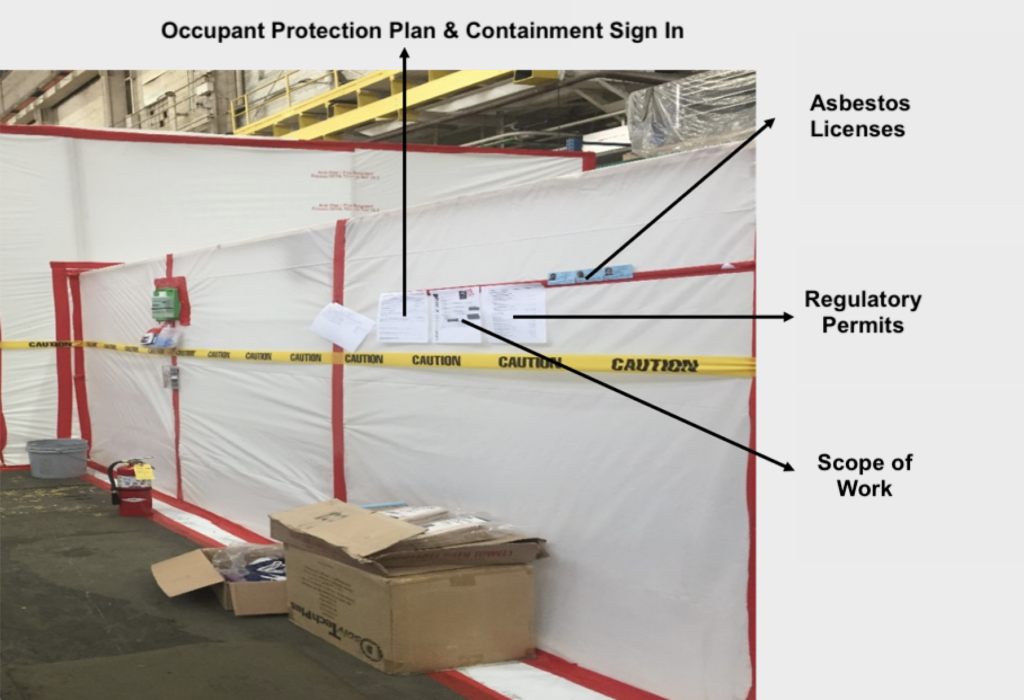

Even with all these steps in place, there are additional safety measures taken. Technicians wear personal air pumps placed within their breathing zone to measure Permissible Exposure Levels (PEL). All technicians complete a minimum 4-day state certified training course and are licensed to remove asbestos. The asbestos contractor files and completes regulatory notifications, city permits, daily sign-in sheets, and occupant protection plans.

And as to what they are doing in there? Well, there are a number of things that could be going on, from removing and replacing pipe insulation to tile removal.

While it isn’t a regular occurrence to come across an asbestos abatement setup, the next time you see one, you can rest easy knowing these procedures are in place for your safety and the safety of others. Pay no attention to the men behind the curtain.